Market Research: Before producing Luxgrow grow lights, we first conducted market research to understand market demand, target user groups, and competitor product features. This helps determine product positioning and design direction.

Product Design: Based on the market research results, we conduct product design. Key parameters such as the lamp's power, spectral distribution, light intensity, and external structure must be considered during design. In particular, the unique light bar design of Luxgrow grow lights requires special attention to the layout and angle of the lamp arms to ensure uniform light distribution and coverage.

Material Selection: We select high-quality key materials and components, including LED lamp beads, power drivers, heat sinks, housings, and lamp arms. These material selections must take into account factors such as product performance requirements, cost control, and environmental standards.

Procurement and Inspection: We rigorously inspect and test purchased materials to ensure they meet product quality requirements.

LED Light Board Fabrication: The LED lamp beads are soldered onto the light board according to the designed layout to form the LED light source module. This step requires precise control of soldering temperature and time to ensure a secure connection between the LEDs and the light board.

Power Driver Assembly: Assemble the power driver assembly and connect it to the LED light source module. The power driver is responsible for providing stable current and voltage to the LEDs, ensuring proper operation.

Heat Sink Installation: Because LED light sources generate heat during operation, a heat sink is required to prevent overheating and damage. The installation location and number of heat sinks should be determined based on the product's power and heat dissipation requirements.

Luxgrow Shape Assembly: Attach the lamp arm to the heat sink or housing according to the designed angle and layout, forming a spliced shape. During this step, pay special attention to the arm's stability and flexibility to ensure the lamp remains stable and easily adjustable during use.

Casing Assembly: Assemble the LED light source module, power driver, heat sink, and arm into the housing to complete the grow light. The housing not only provides protection but can also be designed with various colors and materials.

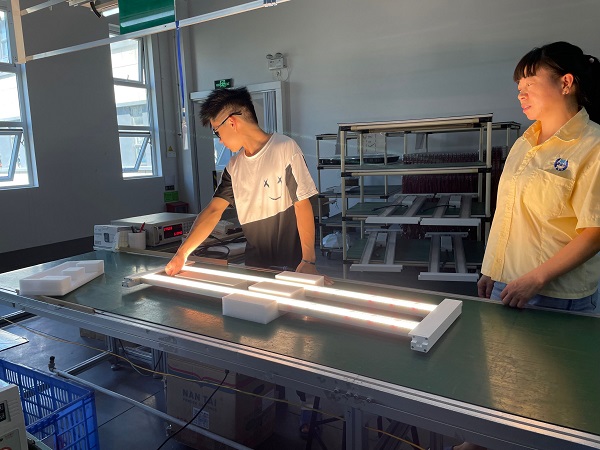

Photoelectric Performance Testing: The assembled Luxgrow grow lights undergo photoelectric performance testing, including testing of light intensity, spectral distribution, and luminous efficacy. This ensures that product performance meets design requirements.

Electrical Safety Testing: Electrical safety testing is performed to ensure that the lamps will not cause electrical safety incidents during use.

Debugging and Optimization: Debugging and optimization are performed based on the test results to improve product performance and reliability.

Packaging: After testing and optimization, the Luxgrow grow lights are packaged for transportation and sale. The packaging materials must provide good protection to prevent damage during transportation.

Factory Inspection: Packaged products undergo factory inspection to ensure that each unit meets quality requirements.

Luxgrow is developed by photology engineers and more than 13 years R & D engineers team in led lights

As a professional and rich experience grow light designer and manufacturer for indoor greenhouse farms ; Luxgrow really knows offer the exclusive customized layout service is very necessary and cost-efficient.

We offer free exclusive customized layout service for customers , not only in the lighting configuration help,but also help you know the budget

Whatsapp

Whatsapp