Multi-layer, high-density cultivation features high space utilization and multiple plant layers, potentially involving plants at different growth stages. Therefore, lighting selection must consider factors such as light uniformity, energy consumption, heat dissipation, and spectral requirements.

Indoor cultivation, such as vertical farms or multi-layer greenhouse cultivation, requires efficient and space-saving lighting solutions. Cost, maintenance, and lamp life may also be a concern. Recommendations are needed for lighting types suitable for different plant growth stages, such as whether full-spectrum LEDs are suitable or whether specific wavelengths of light are required.

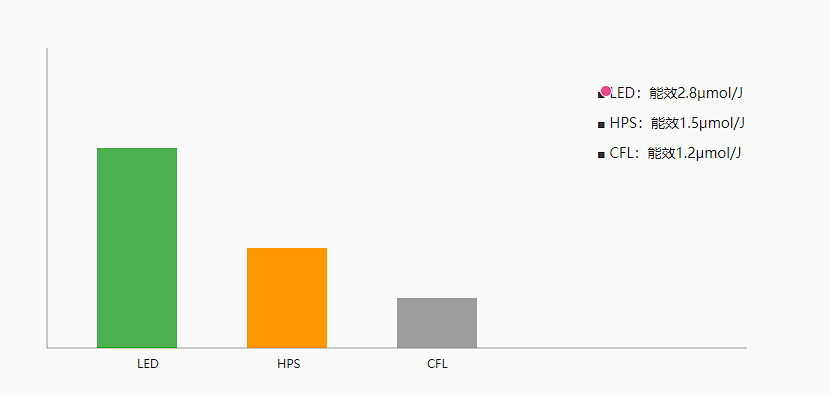

When selecting lighting for multi-layer, high-density cultivation, key parameters such as light efficacy, energy consumption, and spatial compatibility must be comprehensively considered. The following is a professional selection solution:

Layered Lighting Strategy

Canopy Lighting: Utilizes a combination of 660nm and 730nm far-red light to promote photomorphogenesis

Mid-layer Lighting: 450nm blue light + white light with a composite spectrum to regulate photoperiod

Base Lighting: 380-400nm UV enhancement to induce secondary metabolite synthesis

Three-dimensional Hydroponic System

Utilizes waterproof linear light strips (IP67)

Mounting Spacing: 25cm vertically, 40cm horizontally

Reflector Configuration: 95% reflectivity nano-coating

Tissue Culture Multi-layer Shelf

Cold Light Source Configuration (Surface Temperature <35°C)

Double-sided Flat Panel Light (Thickness ≤3cm)

Light Intensity Gradient: Adjustable from 50-200μmol/m²/s

Dense Planting of Fruits and Vegetables

Dynamic Tracking Lighting System (Daily 10cm Height Adjustment)

Light Quality Sequencing (Blue Light Ratio: 30% in the Morning → 10% in the Evening)

Infrared Sensor for Automatic Obstacle Avoidance

It is recommended to prioritize DLC-certified LED lamps, combined with photon sensors for closed-loop control. 3D lighting simulation should be performed before actual deployment to ensure that the coefficient of variation of PPFD of each layer is less than 12%.

Luxgrow is developed by photology engineers and more than 13 years R & D engineers team in led lights

As a professional and rich experience grow light designer and manufacturer for indoor greenhouse farms ; Luxgrow really knows offer the exclusive customized layout service is very necessary and cost-efficient.

We offer free exclusive customized layout service for customers , not only in the lighting configuration help,but also help you know the budget

Whatsapp

Whatsapp